Checking in With Fidelity Record Pressing, Whose Oxnard, California, Pressing Plant Has Been Up and Running Since January and Making Many of the Records We Love to Spin

We do love it when a pressing vinyl matter comes to fruition — or, in this case, the actual pressing of vinyl. Back in Q2 2022, we reported on the imminent opening of Fidelity Record Pressing here, and we’re long overdue with an update on when they got the presses rolling, and how they’re doing what they do.

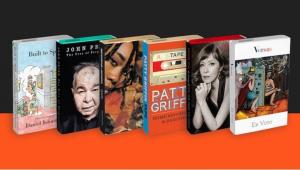

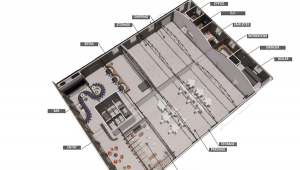

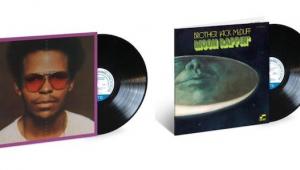

Here’s what we’ve learned. In January 2024, following their two-year-long, from-the-ground-up build, Fidelity Record Pressing officially opened their new Oxnard, California-based facility as the pressing plant for Mobile Fidelity Sound Labs, and they also began accepting vinyl orders from outside clients. “With a focus on exemplary quality” (their words), the Fidelity facility processes and presses vinyl of both current and classic LP recordings for clients who “want to ensure music lovers enjoy flat, quiet, balanced, perfectly centered LPs that honor both the artist and listener.”

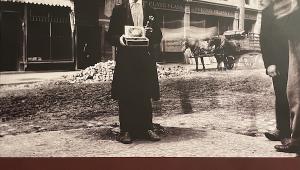

Some further background now. Fidelity Record Pressing was co-founded by Music Direct President Jim Davis in partnership with Rick and Edward Hashimoto, a father-and-son team (seen above) with more than 70 years of collective pressing-plant experience. Rick began his career in the mid-1970s at Record Technology Inc., where he oversaw plating and pressing departments and assisted in the development of the HQ-180 profile mold. During his childhood, Edward shadowed Rick at work and, after college, chose to pursue vinyl manufacturing — and we’re all glad he did.

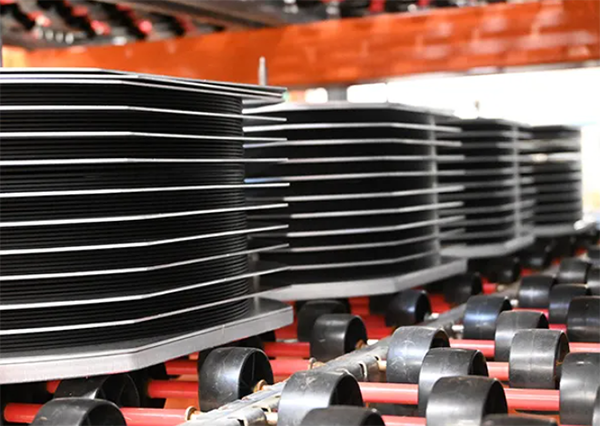

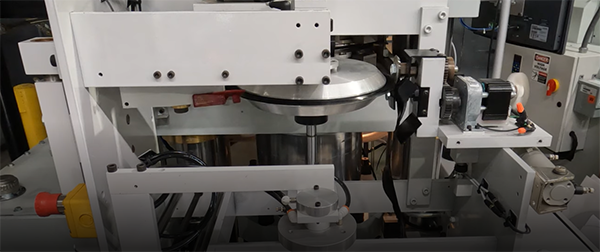

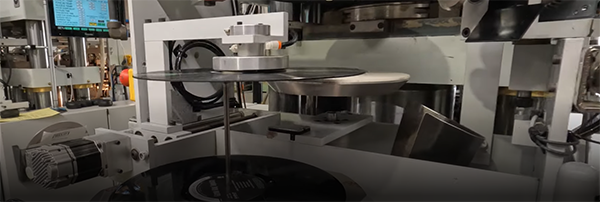

According to Fidelity, the company’s SMT replica record-pressing machines are “the strongest, most rigid designs available today.” The Fidelity presses are hooked up to a new boiler and cooling system, with the process piping having been custom-designed by Edward.

Fidelity uses a premium vinyl compound made by Neotech, the proprietor of the MoFi SuperVinyl compound created in conjunction with the Hashimotos. According to the company, Fidelity uses “proprietary pressing techniques to make the records have a consistent pressing surface and equal heat distribution.”

The records themselves completely cool and cure overnight before being readied for packaging. When it comes to handling those records, Fidelity points out that their team wears gloves, holds each record by its edge, and hand-inspects every one of them. They also “regularly do an audio check of the records during production to further ensure optimal quality.” Additionally, Fidelity uses specially tailored spindles and custom-fit bins during the production process.

According to official press materials, Fidelity’s M.O. is exactly what we like to see, and hear: “Fidelity Record Pressing is targeted to record labels and audiophiles who cherish vinyl and expect the finest sound recordings. Fidelity Record Pressing is dedicated to exacting control, inspection, consistency, precision, and craftsmanship — and realizes there is no substitute for excellence.”

For more about Fidelity Record Pressing, go here.

Fidelity pricing and services information can be found here.