Italian Speaker Manufacturer Sonus Faber Breaks the Mold Celebrating Its 30th Anniversary

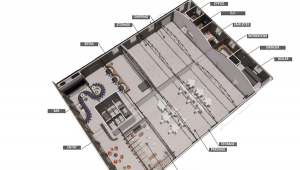

The celebration’s focal point was the all new Ex3ma loudspeaker, which was developed over the past year and a half by Sonus Faber’s design team using as its inspiration the original 1991 Extrema, a legendary stand mounted design that extracted maximum and at the time seemingly impossibly performance from a two-way loudspeaker.

Beginning with its dramatic, angular shape, in no way does the new X3ma resemble the original design, or, for that matter, any previous Sonus Faber product.

Everything about the Ex3ma is new from the outside in, beginning with a complex shape carbon fiber monocoque skeletal structure produced by multi-layers of carbon fiber damped in between with layers of wood laminate and rohacell foam applied to a mold that’s then “cooked” in an autoclave to produce an incredibly stiff, strong, yet low mass, non-resonant structure.

The handsome wood accents of solid Red Spruce from Val di Fiemme, also used in the production of musical instruments, are CNC machined to produce irregular three-dimensional shapes that complement the carbon fiber structure to give the speaker its “Sonus Faber-iness”.

Thick, heavly hand-finished front and back panels CNC machined from Avional aluminum alloy billets attach to the carbon fiber structure sandwiched with copper sheets and visco-elastic decoupling agents.

The drivers, developed in-house by Sonus Faber engineers make use of various metals, nano-carbon structures and a physical vapor deposition based tweeter of Beryllium that’s then coated via the same process with a layer of DLC (Diamond Like Carbon) to produce a well damped metal dome.

The tweeter is truly an international product. The beryllium dome comes from America, the diamond vapor deposition is done in Germany, the rear support structure is made from Ergal aluminum alloy as well as Gun Metal—an alloy of copper, zinc and tin milled in Italy and final assembly takes place at Scan-Speak in Denmark.

The 7 inch mid-woofer uses non-carbon and a special damping foam as well as a combination of metals to form the massive basket structure. The mid-woof features a 6N pure copper wire coil wound on a controlled “eddy current” former.

A rear mounted, “race track” shaped passive radiator fitted with a flat piston diaphragm that resembles ones used by KEF many years ago as well as a motor that can be adjusted via a rear panel mounted to switch to one of five positions to vary the amount of damping. Sonus Faber calls this arrangement the “L.E.M.B.A.B.R” (Electro Magnetic Brake Auxiliary Bass Radiator).

Thus the speaker can operate at one extreme as a quasi-sealed box (maximum damping) and as a quasi-ported speaker at the other depending upon personal preference and room placement

The 2350Hz crossover uses the highest quality Mundorf Supreme capacitors, Jantzen inductors, each three-dimensionally hand built by Research and Development manager Paolo Tezzon using point-to-point construction with Shunyata hook-up wire.

The included stand makes use of similar damping and copper sandwich construction techniques.

Response is said to be flat to around 38Hz with smooth roll-off from there and up to 40kHz. Most importantly the new speaker’s efficiency is 88dB, which is the same as the original Extrema, but the new speaker is much more easily driven.

Only 30 pairs will be manufactured and sold factory-direct through the auspices of S-F dealers. Serial numbers will run from 1983 to 2014.

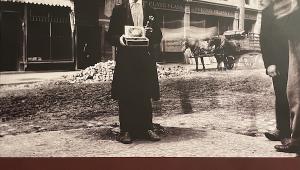

Less cynics think Sonus Faber might go back on its word and produce more Ex3mas once the 30 $50,000 pairs have been sold (which should already have happened), Fine Sounds CEO Mauro Grange held a mold smashing ceremony Friday afternoon outside company headquarters.

As 250 or so witnesses watched he donned a pair of white gloves and grabbed a large, heavy sledge-hammer. I had my GoPro camera on to record the event but without warning Mr. Grange grabbed me out of the crowd and asked me to join him in the smashing. Watch the video: