Minus K's David Platus Takes the Stand On Behalf of His "Negative Stiffness" Isolation Technology

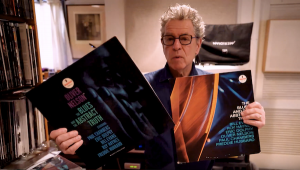

While effective isolation from both air and ground borne vibrational energy is important throughout the audio playback chain, it is essential for vinyl playback. It can be built into a turntable in the form of spring or "O" ring suspensions but current thinking downplays that in favor of separate isolation stands rather than incorporating it into the turntable itself.

While effective isolation from both air and ground borne vibrational energy is important throughout the audio playback chain, it is essential for vinyl playback. It can be built into a turntable in the form of spring or "O" ring suspensions but current thinking downplays that in favor of separate isolation stands rather than incorporating it into the turntable itself.

Why? Spinning platters, no matter how carefully machined and/or balanced spinning upon a spring-suspended platform, will inevitably set the platform in micro-motion. If the motor is isolated by being placed upon a sub-platform for example, the motion of the sprung platform will vary the distance between the belt and motor, causing micro speed variations. This can often lead to a pleasant, warmish sound at best, though it is an undesirable coloration, or at worst to sonic mush.

Stabilizing such platforms with damping troughs or built in pneumatic stabilizers can help and some older designs such as Oracle's Delphi have benefited greatly with the addition of silicon troughs beneath each spring tower. It's easy enough to run the latest Delphi with and without the damping troughs engaged and the differences are not subtle.

For these and other reasons, many manufacturers are opting to design and build non-suspended turntables, which gives end-users the option to add an aftermarket isolation platform. These can be relatively inexpensive but reasonably effective ones like the Gingko Audio Cloud that utilizes squash ball-like devices sandwiched between two polymer platforms or more sophisticated ones like those from Halcyonics and the Vibraplane from Sounds of Silence Audio that uses sophisticated pneumatic air suspension devices incorporated within a very heavy metal platform. This technology is based upon devices manufactured by Newport Corporation and is more typically used in electron microscopy stands. It is also what was used in the no long manufactured $80,000 Rockport System III Sirius turntable.

The Halcyonics and Vibraplane platforms are active systems. Roughtly speaking, the Halcyonics platform uses an elastomer based suspension and piezo-electric elements that react to vibrations entering the system. The Vibraplane comes in two models: one is passive and requires end users to occasionally refill the air bladders with a pump. The active version requires an outboard electric compressor that activates when the system pressure goes below a certain preset level.

There's a more recent addition to the isolation platform "community" invented and marketed by MinusK that, like Newport, is headquartered in California. Unlike the others though, the MinusK is completely passive. That is, it does not depend upon either electrical or pneumatic devices to provide isolation, nor is it reactive. Another completely passive platform is manufactured by Harmonic Resolution Systems. The designer, Michael Latvis is a vibrational engineer who in his spare time designs helicopter rotor damping systems among other things for the military. I use the HRS racks for my components and for reviewing turntables. It's what Brinkmann offers as an option for its turntables and it works very well.

Of course there are many, many isolation stands manufactured specifically for audio, some of which have been designed by competent engineers, but others are just Gyro-Gearloose contraptions based upon fanciful but hardly scientifically credible notions.

Like the Newport-based technology, Minus K's platforms, which are available in a wide range of sizes and weight capable models, are mostly used in the medical, scientific research and electron-microscopy fields.

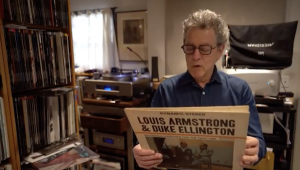

I was made aware of these Minus K devices by Mark Doehmann, the former Continuum Audio Labs designer, responsible for conceptualizing the design and overseeing the manufacture of the Continuum Audio Labs Caliburn turntable, Cobra tonearm and Castellon stand that I've used as a reference for the past seven years. It's hard to believe it's been that long but that's how long it's been! In all that time the turntable has given me zero problems. It's been 100% reliable, which is the least one should expect from a turntable that ended up costing $150,000 dollars!

Ridiculous? You should hear it some time. Audiophiles used to at shows where Continuum displayed, but those were often marred by poor associated gear. However, CD-Rs made from the 'table never fail to amaze people, though of course live play back is even better.

I was fortunate to buy the review sample early on when the projected retail was around $90,000 and since mine was an early, failed experiment in chrome plating magnesium that resulted in a cosmetically unacceptable finish, I was able to get it for the cost of a nice car. It took me a few years to pay off the loan, but it's my favorite material possession and something for which I have no regrets buying. I've yet to hear another turntable that can match its sonic performance.

So, to make a short story long, the Castellon stand incorporates a reasonably effective magnetic repulsion platform that "floats" at a very low frequency. The horizontal part of the system incorporates a thin diameter rubber inner tube that runs around the periphery of the platform. It requires pumping up a bit every few weeks. Overall the system is very effective because you hear the need for air well before you see that the platform has settled somewhat.

Internal company politics were such that replacing the magnetic isolation stand with one by MinusK would void the turntable's warranty. Yet a few Caliburn owners (of which I think there are at least one hundred or perhaps more) did make the switch, including one in California whose turntable was located on a springy second floor and suffered the dreaded and all too familiar to vinyl enthusiasts foot fall induced arm jiggling and skipping, despite the Caliburn's very effective magnetic isolation system.

This owner and a few others told me that the addition of the Minus K technology took an already amazing turntable to a whole new sonic performance level and that it also totally eliminated foot-fall based stylus-skipping issues, though that's not a problem in my concrete slab floor located listening room.

I didn't wish to get involved in the company politics but since my warranty has expired, when one Caliburn owner bought a Minus K and then chose not to go through with the modification (for reasons that had nothing to do with its claimed performance) and offered it to me for his cost, I gave in and bought it.

The Minus K modification for my turntable involved removing the original magnetic isolation system and dropping the 'raw' guts into the Castellon stand so that outwardly nothing appears to have changed, though the mechanism does hang below the platform, which the original did not do.

The sonic difference was "as advertised" to me by one of the Continuum owners: (among other sonic benefits) the blackness of the backdrop, which already was noticeably superior to any turntable I'd heard got even blacker and took the term "silence" to new levels. Another Caliburn owner was so impressed he bought a self-contained unit and put it under his DAC. He says it made an equally profound difference.

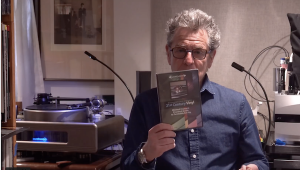

So, to get the scoop on Minus K, I contacted the inventor David Platus and what follows is a transcription of our discussion. It would be very helpful for you to click here technology, copy the link and open in another browser window before reading further.

Michael Fremer: This technology was explained to me in simple terms as isolation created with “bending springs.” Is that was causes the effective isolation?

David Platus: Well, we use something called “negative stiffness.” One example is the old oil cans where you squirt by pressing the bottom? The bottom of that can is basically a negative stiffness mechanism. You can’t keep it centered. It’s either popped out or it’s popped in. Basically it acts as the reverse, as a negative of a spring.

After coming up with this idea, I was one of the early casualities of the economic slowdown in defense and aerospace spending in California, so I had time to review what was going on with air isolators and I found out that they wouldn’t exactly work for super-low vibrations. So I came up with the concept and the Air Force didn't want to develop it, so I got laid off from the company for which I was working, so I said “I’m going to develop this thing.” I guess it was kind of naïve…

MF: So this was the mid ‘90s?

DP: This was 1988 and the company didn't want to develop it so they ended up giving it to me, you know, the initial germ of the idea and kind of an added severance. They said “we wish you luck.” And that’s basically what happened. I did some consulting after that but devoted four or five years almost full time working with an associate coming up with the patents and building prototypes. Finally we attracted some capital and started the company and incorporated in 1993. It was just me and a couple of people part time for a few years trying to figure out what to do with this thing.

Fortunately, the technology moved in our favor, moving towards everything small: nano. Nanotechnology. So we started selling finally, making improvements along the way and that attracted some more good people.

MF: Now can this technology be made really small?

DP: The smallest things we ever made were 6” diameter and 4” tall and these were going into an ultra high vacuum chamber for science work where they literally move atoms around and build new structures. That’s what nano technology is all about.

MF: And your background is in?

DP: Well I have a varied background. I started in chemical process engineering, went to U.C.L.A. where they emphasize a generalized curriculum. The Dean at the time said engineers end up in different fields and we want to give you the fundamentals. So it was like chemical processing was a major. And then I got into the nuclear field. I went to a special school where I learned to design nuclear reactors. I worked in that field for a very short time, then got into working on a nuclear airplane engine and then into the structural mechanical aspects.

MF: Is it true that you won a contract to develop the lunar landing module suspension system?

DP: No I came up with an idea, which they used, to support the crew couch in the Apollo command module. Basically kind of a fancy shock absorber in the very limited space between the couch that the three astronauts rode in when they went orbited the moon. And if they had to abort the flight shortly after lift-off and the winds are blowing inland the capsule could land really hard and injure or kill the astronauts. So they were looking for the best possible energy absorber—especially after that tragic fire where three of the astronauts were killed on the launch pad. And they ended up with my invention for that.

MF: That must be satisfying.

DP: Very! That was early in my career. I was just a young guy out of school.

MF: I want to continue with this, but I want to give you a website to look at because there’s this whole thing happening in the audio world with Quantum Physics and Quantum Mechanics. Weird stuff like little tiny stick-on things that supposedly have enormous sonic effects.

DP: Yes (laughs)! One of my associates showed me something like that: little beads you hang on cables. Crazy! This strikes me as very humorous. Let’s go to the Minus K.com website and click on the technology toolbar on top and then “negative stiffness isolators how they work”.

See that figure 1? That’s a pretty good representation of how our vertical isolator works. Now imagine the 3 balls connected by two beams. Take the spring away. So now picture the three balls aligned. And you are squeezing that from the sides. That center ball is in a state of unstable equilibrium. It wants to pop up or pop down. That’s like the middle of the base of the oil can. If you let it be displaced up just a little bit, it takes a force to hold it in equilibrium. Now for small deflections if you double the displacement, it’s going to take double the force. And if you triple the displacement it’s going to take triple the force.

So there’s a force displacement relationship, which is really what the stiffness of a spring is. See, to deflect a spring upward you have to pull it upward. It takes a force to hold it. If you pull it up a little bit it takes a small force, if you double the deflection, twice the force, if you triple the deflection three times the force.

So you have a “spring constant” or spring rate, or spring stiffness. But this device is the negative of a spring, because if the displacement is up, the force is down. If the displacement is down to hold the negative stiffness device in equilibrium, the force is up. Mathematically, the negative stiffness part of this design is the reverse of a spring. In the actual isolators we use flexure. We don’t want any friction or “stiction” or anything like that.

So now when you combine that with a spring as in our animated illustration, the spring supports the weight load, whether it's a few ounces or ten thousand pounds. But now, with the right design of that negative stiffness mechanism, you literally take the stiffness out of the spring. Now you have something that supports the weight load that’s got the stiffness of a slinky. Very low stiffness. You can actually make the stiffness go to zero.

That’s how it works. It’s very simple in principle. Another way of looking at it is, if you took away the squeeze force (the “p” load in the animation)? And you just pushed down on the spring and deflected it unit displacement with whatever force it takes to deflect it unit displacement, that’s my definition of the spring rate or the spring stiffness: pounds to deflect it an inch.

But now, when you have this mechanism helping you, it’s like a servo-assist or something. You push down a little but, but now it’s pushing for you. So you don’t have to push as hard. That’s almost an easier concept. So now, if you don’t have to push down so hard to deflect that thing it’s got a lower spring rate, lower stiffness. And that’s what you want in an isolator. You want something that supports a weight load with a very low natural frequency because when the table or the ground or whatever is shaking underneath, you’ve de-tuned the system.

And you want a very low natural frequency. And the lower the frequency, the better. That’s what the Air Force was looking for. They were going to build an active system around a super super low natural frequency system—something that’s almost unheard of today.

MF: And they were going to use air?

DP: No. They were going to start with this passive isolator, which we were going to provide using my concept and then they were going to build an active system around it. All of these active or electronic cancellation systems use a spring of some kind. It could be an elastomer or something that they build the active system around and the Air Force was going to build an active system with a super, super low frequency passive system and that’s where I conceived of the idea.

MF: I see. And how does this maintain its level?

DP: Okay, so this is only the vertical. Now go down (on the website) to the next figure 2: and again, that shows a planar example of a payload sitting on what we call a beam column. Just a flexible rod. Now on the right side drawing, the rod is pushed over to the right. And it’s got a weight load on it. See, there’s something called an “inflection point” where there’s no curvature right at halfway up the beam column? Because the curvature changes. There’s no bending moment. You know what a bending moment is? A bending moment is just like a torque that causes the beam to bend.

So basically you can analyze this as little cantilever beams. Like a little flagpole coming up from the bottom and one coming down from the top. So it’s legitimate to show this thing as a little cantilever beam and it’s got a horizontal force on it. This is the way we isolate horizontally.

So, if you didn’t have any weight load (showing the weight load and the payload on that little column?) it acts just like a horizontal spring. It takes a horizontal force to deflect it and if you want to deflect it twice as much, twice the force. But see, now when you put a weight load on it the weight load acting on the deflected beam causes additional bending.

MF: Yes I can see that.

DP: Especially at the root. The maximum added moment is right at the root. So when you put weight on it, it makes it easier to bend the beam. In effect, it makes the beam act like a spring and a negative stiffness mechanism. And the more weight you put on, the more negative stiffness you get.

MF: So the better.

DP: And the better until you reach a point where it goes totally unstable. That’s called “the critical buckling load.” So we operate just below “the critical buckling load.” So it will always come back, but it’s like the slinky again. It’s got a super-low stiffness. And that’s what we do for horizontal. And so now, we combine that in a compact unit that’s got the vertical and the horizontal and that’s show in Figure 3. That’s a pretty good representation of all of our isolators.

MF: So what I’ve got under my turntable is within the stand so I can look in and see all of these components. In your case it’s a little different because there are two springs instead of one, but basically there’s a spring and series of these compressed horizontal flexures. But see, they’re compressed like the beam column. They’re compressed beyond their “critical buckling load.” So they not only take out their own stiffness, but they take out the stiffness of that vertical coil spring that’s supporting the weight load.

So now the vertical motion isolator is… the coil spring is analogous to the coil spring in figure 1. And those compressed flexures, compressed again with a spring, see that screw over to the left (on Figure 3) that says “Vertical Negative-Stiffness Flexures”? And they look like lines. All they are, are sheet metal flexures. And there’s a set of them that goes to the center, just like that center ball (in Figure 1) and then they go to the left to a rigid support and they go to the right to a support that can move in and out that’s got a spring in it and that screw goes right through from the left support to the right support and as you tighten that screw you put more vertical negative stiffness into those flexures. You can literally turn that screw and watch the frequency of your system change.

MF: So you manufacture for different essential load ranges?

DP: Yes. Every standard product we manufacture gives you the dimensions, the range of weight loads and so on. And now if you go to that center hub? That center block? Upper spring support (Figure 3)? There’s a support shaft that goes from the top of the spring down to that dark gray charcoal thing at the bottom, the Lower Column Plate. See, that plate moves up and down with the vertical motion isolator. So now we attach a set of these beam columns to that lower column plate and it goes up and then we attach an upper column plate. Now we’ve got horizontal motion just like I showed you in Figure 2.

A weight load, loading these columns and you load them near the nominal capacity of the isolator and you get that very low horizontal natural frequency.

MF: So the key is to make sure that the structure itself is level.

DP: Yes. When you get very low natural frequency you have to level the frame otherwise there will be a little component of gravity that pulls the thing laterally into a stop. So that’s basically the whole isolator.

So that’s why we call these things “negative stiffness isolators”. By using negative stiffness we get these very low natural frequencies. Lower than any practical thing on the market.

MF: And people can buy this directly from you?

DP: Yes. If you click on “products” it lists all of them. The big SM-1s we use as floor platforms and then you go down to the benchtops and so on and then you click on pricing and specs you see how big they are, what the weight ranges are, everything. So yes, people buy these things directly from all around the world.

MF: Okay. I think I understand it now. I can’t believe I didn’t think of it myself!