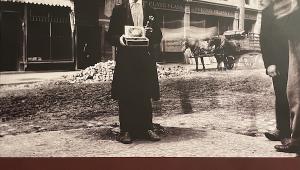

This is What IGOR "Stitching" Looks Like

Thi pressing defect was originally identified as "non-fill" but it is not. It is "stitching". When you are at a "Making Vinyl" event with three of the world's greatest authorities on lacquer electroplating and also many of the world's best pressing plant owners, trust me, you get your mistakes corrected! I thought "stitching" and "non-fill" were synonymous but they are not. There's always room for learning.

"Stitching occurs when the separation of pressed vinyl from stamper is faulty or when the stamper is improperly pulled from the mother in which case every record pressed from that stamper will look like this and there's no excuse for it not being caught and corrected. The defect runs around the groove circumference. "Non-fill" is when a patch of vinyl separates from the pressed record and usually looks like a white spot...