Zenith Angle Correction: The Final Set-up Frontier!

If you think otherwise, or if you think you can "dial in SRA by ear" you are wrong. If you pay someone to set up your tone arm who dials it in "by ear", you are not getting your money's worth! Here's proof:

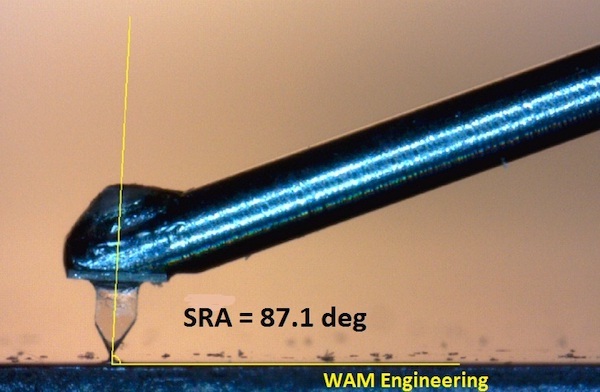

This image is the stylus of an expensive cartridge ($6000+) with the arm set parallel to the record surface. If the buyer or installer thinks he can set SRA by "ear" by moving the back of the arm up or down, he (or she) is clearly wrong! To achieve 92 degrees here on a 9" arm, you'd have to raise the back of the arm 20 millimeters— a ski-slope of an angle! Without a microscope, the buyer or installer would simply "fiddle" with the arm, moving it up or down small amounts and never get near where the arm has to go to reach 92 degrees. Faced with this image, the best thing to do is return the cartridge and demand a properly manufactured one, especially when the cartridge costs many thousands of dollars.

That is why SRA must be set using a microscope and azimuth must be set using either a voltmeter or a digital oscilloscope. These tools are available for a reasonable amount of money (around $500 for both). Reasonable especially if you spend thousands on a cartridge! Some acquired skills are necessary to use these tools.

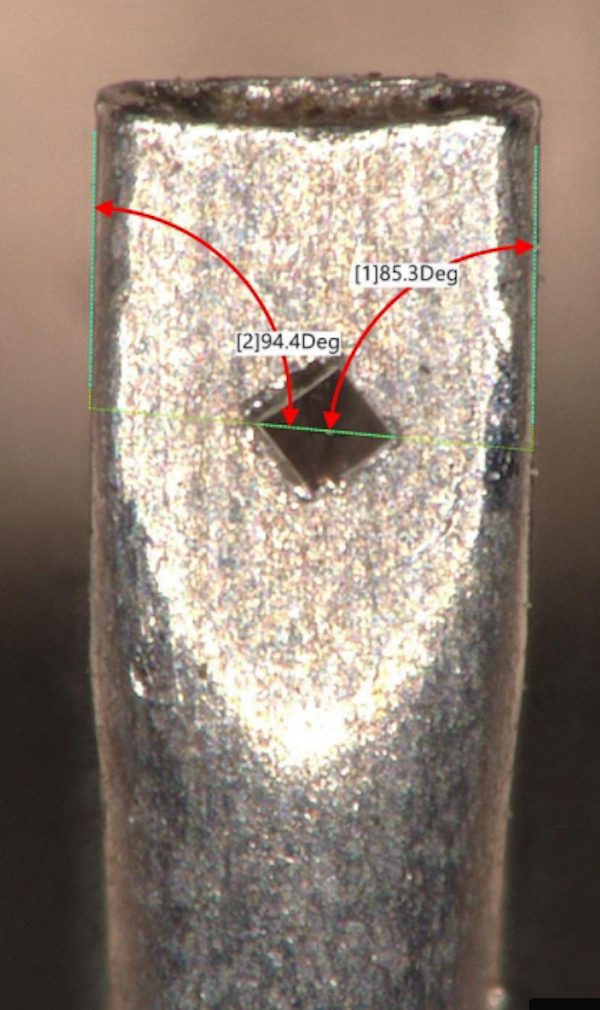

Everyone reading this who installs his or her own cartridge uses the cantilever as the guide for setting zenith angle, which is what you set after you get the correct "overhang". Unfortunately, as the photo at the top indicates, even that setting is unreliable! The costly microscope used to produce that image shows an expensive cartridge's stylus inserted into the cantilever at an angle that's around 4% "off". The result is that the stylus reads one side of the groove before the other. This problem gets exacerbated the further towards the center of the record the arm travels, resulting at the very least in gross phase distortion.

The photo supplied by Wallytool's J.R. Boisclair makes clear that setting zenith angle, like the other set-up parameters cannot be done reliably "by eye"—unless the stylus/cantilever assembly (at the very least) has been correctly manufactured, and based upon his experience, too many are not! (Note: the measurement showing the zenith error is NOT done by evaluating the side facets of the shank relative to the cantilever as most readers would infer upon seeing it. The measurement is of the contact edges, which here, are partially obscured by the green angle line).

Unfortunately the prohibitive cost of the microscope makes this parameter impossible to correctly set "at home", but there is a solution.

Wallytools offers (or will soon offer) a service whereby you send your new cartridge to them for inspection. It will be returned with a full report detailing the variances (if any) from the ideal that would allow parallel to the record surface and cantilever perpendicularity to correctly set SRA and azimuth and cantilever placement parallel to the "hash" or grid lines to set zenith angle.

Best of all, the service can also offer (at additional cost) specially designed shims that will allow you to set SRA and azimuth without any measurements by you at all, and this applies also to arms like Rega's that don't offer any options for azimuth or SRA adjustability. Wallytools is working on a multi-angled zenith angle gauge that will allow you to accurately set zenith angle for your cartridge based upon the degree to which the stylus is "off". All of this is currently "in the works". The inspection cost alone will not be inexpensive and certainly if you're spending $500 or so on a cartridge such a service would make little sense, but if you are buying a $5000 or even $10,000 or more cartridge, it would be foolish to not take advantage of this service, if just to find out if your cartridge has been correctly manufactured.

The best way for this to work, would be if manufacturers or importers sent all of their new cartridges to Wallytools for evaluation, with the cost tacked on to the cartridge cost so that when you by it, it comes with the full report "out of the box". That may happen too.

Stay tuned for further updates as this service becomes fully operational. In the meantime, setting zenith angle is at best approximate, I'm sorry to tell you. By the way, the top image is of my old Transfiguration Temper Supreme, it was returned to me with a full report prototype and a gauge that will allow me to correct for the 4 degree (gross) zenith angle error produced by the misaligned stylus. Mr. Boisclair used blind testing to prove that correcting this error is easily audible and produces a major sonic benefit.