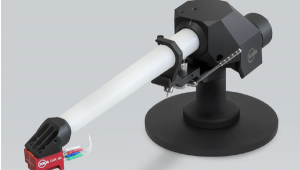

Airon Audio TH1 Tonearm

A new tonearm design might not seem as “sexy” as a new turntable design is, but there’s good reason to give them some love too. Some tonearms warrant more attention than others, and the latest entry from Airon Audio, the TH1, caught my eye at the High End Munich 2025 show back in late May. I made a note to write about it in more detail after getting back from the show — and that time is now.

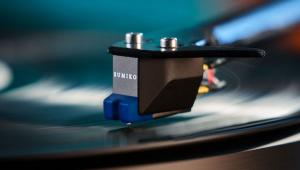

The Airon Audio TH1 tonearm was shown alongside an outstanding-sounding active demo that took place inside one of the show’s purpose-built “cabins” in Halle 4. The active demos were presented with other passive displays in collaboration with Soundsmith Audio, who introduced a couple of new cartridges (more news to come on said carts at a later date).

Essentially, Airon Audio’s TH1 tonearm is a contactless, air-bearing (or pneumatic) type of uni-pivot arm. Airon’s Julian Lesko explained to me more about how the TH1 works. Primary benefits of an air-bearing approach derive from eliminating material friction and mechanical noise. The amount of air pressure required here is minimal — the equivalent of approximately 4psi of water, which is comparable to the amount of pressure needed to blow a bubble throw a straw, Lesko noted.

The air supply (er, no relation to the band) includes backup power and is reported to be “reliable” with “a quiet, long-life compressor” that allows for remote placement.

The TH1 arm works like a ball-and-socket joint with a precise non-contact damping system — the “Iso-Damp System” — Airon developed for the uni-pivot. The TH1 has a magnetic anti-skate system that can match the skating forces as they change while the tonearm and cartridge track across the record’s surface, Lesko added. Anti-skating and VTA can be adjusted “on the fly” during playback.

The TH1’s “non-contact” design is reported to increase the uni-pivot’s stability — and sound, including improved clarity and nuance. Airon further claims that “by removing friction and mechanical interference, the TH1 reveals the full character of the vinyl.”

How many tonearms are tunable? A knob on the rear of the TH1 arm is connected to a rod going to the headshell, allowing users to adjust the arm tube’s stiffness — which, by extension, enables tweaks to the cartridge’s sound, according to Lesko. “You can dial it to adjust the tension,” he noted. “If it’s tighter, the sound will be more detailed and aggressive; if it’s looser, [it will be] more fluid and ‘listenable.’” This could be an interesting tuning adjustment to try out across various systems and setups — not to mention across musical styles.

The TH1’s arm tube is made of ultra-high modulus carbon fiber and houses Cardas Clear internal wiring. The TH1 arm comes in a standard 10in tonearm length; other custom lengths are available upon request. The TH1 mounts via a secure M30 threaded post. Mounting options include Airon’s own free-standing base (seen above and below), or other armboards that Airon can customize.

Airon Audio CNC-machines their own products that are engineered and made in the U.S. The SRP for the TH1 tonearm is TBD, and once we have that pricing information in hand, we’ll add it in here.

For more on Airon Audio, go here.

To order Airon Audio gear or place an inquiry, email the company directly at Info@aironaudio.com.

Author bio: Julie Mullins, a lifelong music lover and record collector since age 10 who takes after her audiophile father, is also a contributing editor and reviewer on our sister site, Stereophile, for whom she also writes the monthly Re-Tales column. A former fulltime staffer at Cincinnati’s long-running alt-weekly CityBeat, she programs and hosts a weekly radio show on WAIF called On the Pulse.