Thorens TD 1601 Turntable—It Might As Well Be Sprung

The original AR XA turntable designed by Edgar Villchur and introduced way back in 1961 for $58 was, to the best of my knowledge, the first to place the platter assembly and tone arm on the same sub-chassis isolated by a three point spring mount from the rest of the turntable (and from the outside world).

The previous incarnation of the Thorens brand, founded by Heinz Rohrer, had in the mid- 2010’s launched the TD 900 series also featuring the classic sprung chassis, but prices ranged upwards of almost $10,000 and the looks were “industrial”.

Producing a moderately priced, cosmetically suave turntable that lived up to the rich heritage and impeccable reputation of Thorens’ TD 160 was a formidable task for Thorens GMbH, reorganized last year under new CEO Gunter Kürten—an audio industry veteran and former CEO of ELAC. You can read more about the company’s history in the TD402 review published here in the fall of 2019.

The sample of that budget direct drive model turned out to be a “for photography” edition, which Thorens claims explained the loose arm bearings and other issues noted in the review, though much of its “guts” and the tonearm used were familiar looking “off the shelf” components manufactured at the highly accomplished Taiwan-based contract manufacturer Thorens, among other turntable companies, currently uses.

Other than the equally superlative “fit’n’finish”, everything else about the new TD-1600/1601’s design and mechanical performance is the opposite of the TD402’s.

The new 1600/1601 ‘tables are a “from the ground up” original design created in Germany and precisely executed by the Taiwan-based factory. Only the TP 92 arm, which will look familiar to many of you, is a “holdover” from the previous era.

Other than the TD 1601’s auto-cueing and end of record lift features, the TD 1601 and 1600 are identical. The fully manual 1600 has an MSRP of $2999. The 1601’s is $3499.

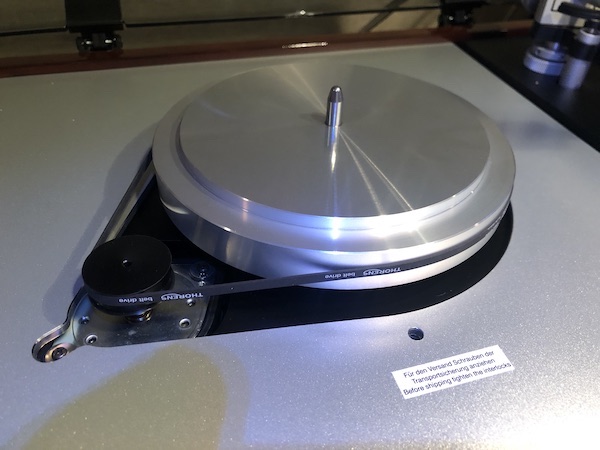

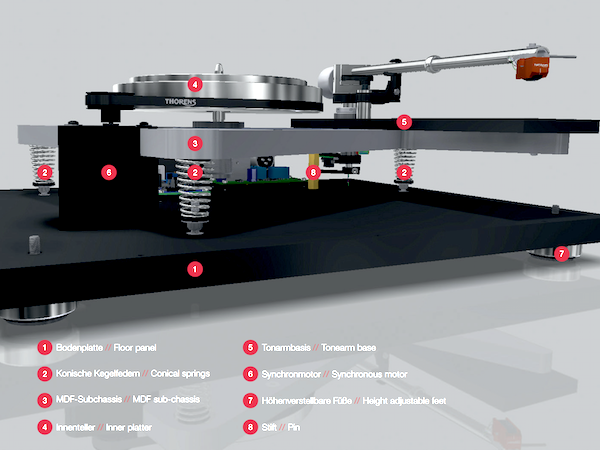

Unlike the original TD 160, which featured a sub-chassis hung from its top plate, the TD 1600’s MDF sub-chassis sits atop three foam-damped coil springs attached to a massive, highly damped base supported by three height-adjustable feet.

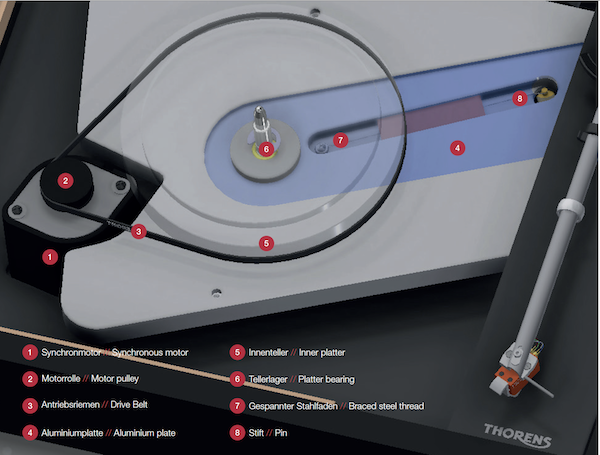

The brushed aluminum top plate/plinth is of Alucobond™—a sandwich of aluminum plates in between which is an aerospace honeycombed material that is said to produce a super-stiff composite.

A newly developed silicone ring-damped 12 volt synchronous motor fed by an outboard 16V linear power supply featuring a large toroidal transformer is encased in a non-resonant housing that’s mounted to the base.

Thorens has effectively addressed one of a suspended chassis’ biggest problems, which is sometimes known as “porch glider effect”— the sub-chassis’ tendency to shift horizontally, produced by, among other things, record eccentricity, but most especially by the motor’s driving forces against the platter.

The MDF sub-chassis features a stability-enhancing aluminum plate insert (blue in the drawing) to which are mounted both the platter bearing and the tonearm. The platter bearing is braced against the base plate with a thin steel thread that runs via a guide along an axis between the motor pulley and the platter axle terminating in a brass tensioning pin also seen in the drawing.

Without such an arrangement, the platter bearing assembly and thus the entire sub-chassis can shift relative to the motor’s fixed position, which can produce belt flexing speed inconsistencies. While placing the sub-chassis atop the springs also improves lateral stability, the guided and tensioned steel thread eliminates it, producing from the three springs the desired pistonic vertical movement.

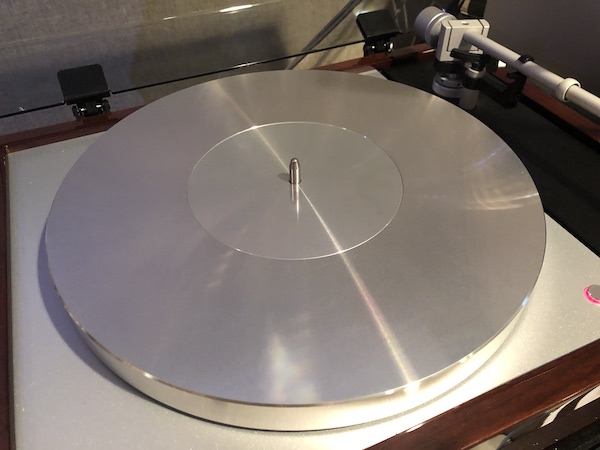

The 7 pound dynamically balanced 12 inch diameter aluminum platter rides play-free on a generously sized aluminum sub-platter sitting upon and mechanically attached to a maintenance-free sealed spindle bearing ((the outer platter weighs 4.5 pounds, the sub-platter 2.5).

The entire spin mechanism exudes high quality, which is not to say it’s perfect: viewed from the side as the platter spins it’s possible to see both top surface vertical movement and clearance variance between the platter bottom and plinth top plate, though both are minor and of little concern. Thorens supplies a moderately thick rubber platter grooved with large “land masses” in between for, as far as my experience tells me, mostly cosmetic reasons.

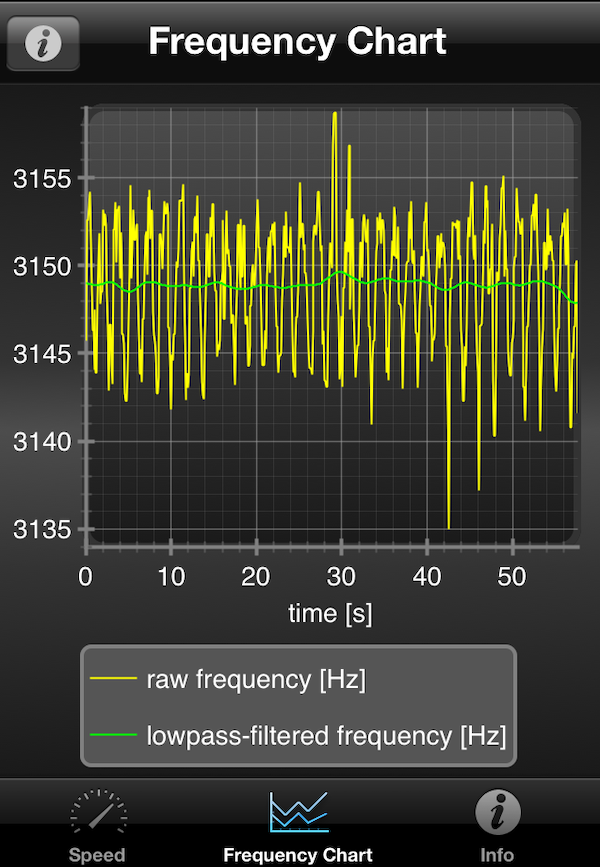

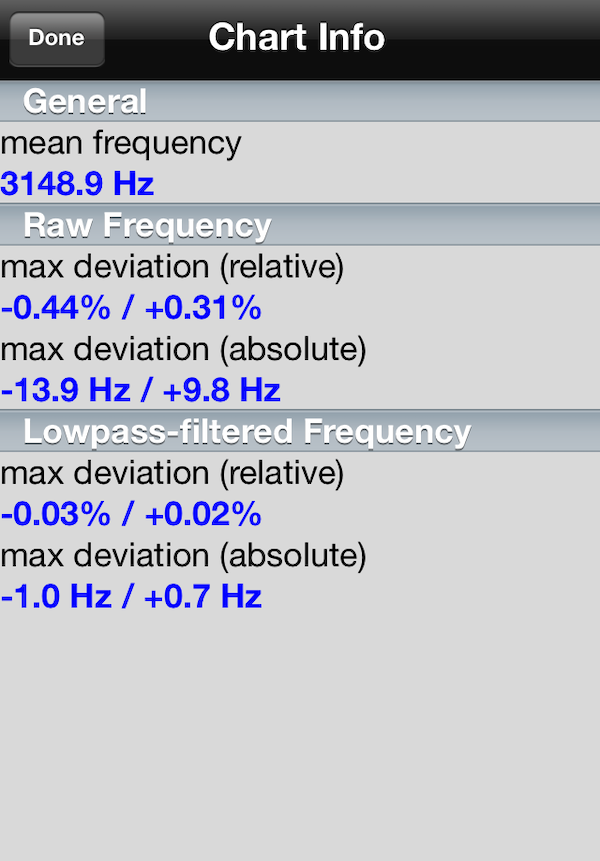

Speed can easily be adjusted via rear panel mounted pots for both 33 1/3 and 45rpm. As delivered the 1601 ran beyond acceptable speed variation tolerances but once adjusted remained accurate. The Platterspeed App measurements show that the Lowpass-filtered maximum relative and absolute speed deviations were both minor producing a relatively smooth green line free. As you can see the raw deviations were larger than you’ll see on direct drive turntables, but those usually produce a “choppier” lowpass-filtered frequency line resulting from constant electronic correction. These measured differences also produce sonic differences, with all else being equal, the DD turntables sounding to some “more precise” and the belt drive turntables sounding “smoother” and more relaxed.

In addition to the back panel’s speed adjustment potentiometers there are both RCA and balanced XLR outputs as well as the multipin power supply jack.