Stylus Zenith Angle: A Heretofore Neglected Set-up Parameter Considered

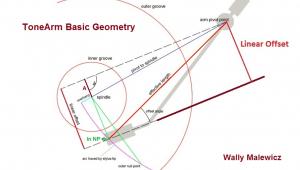

Ironically, if you have a tangential tracking tonearm, this cartridge will never be tangential to the groove at any point in its travel across the record surface!

At one point, for correct zenith angle set-up, we were instructed to be sure the cartridge body was lined up "squared" to the overhang gauge hash marks, but it eventually became apparent that cantilevers were not necessarily aligned with the cartridge body and of course if the body wasn't square you couldn't use the body as a guide anyway. So the instructions changed to "use the cantilever." That's what I have been recommending for years in my seminars.

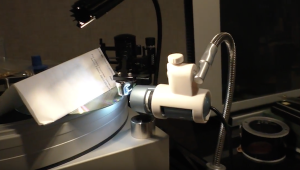

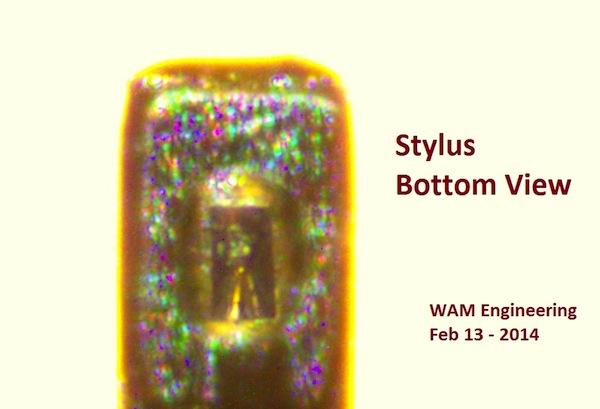

At the same time I say "be sure to get a digital microscope because the odds are the stylus has not been corrected affixed in the cantilever in terms of SRA."

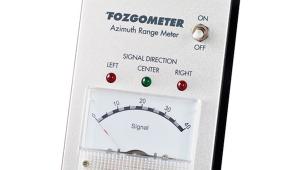

And I say, 'be sure to set azimuth electronically and not by adjusting the cantilever to be perpendicular to the record surface, or the head shell parallel to the record surface."

Why? Because the odds are the stylus has not been inserted perfectly into the cantilever in terms of being "45/45" to the groove center."

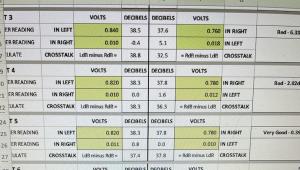

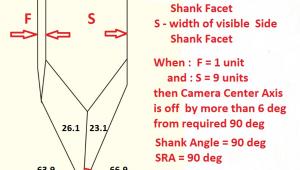

How then could I and everyone else not have considered that the stylus might also be misaligned in terms of zenith angle? I don't know. Maybe out of sight out of mind. I just never thought about it. Until this image arrived in an email.

But now, what to do about it? Obviously using the cantilever to set the zenith angle isn't 100% reliable but let's say you look under a microscope and see this kind of picture. Do you try to compensate for the angle by twisting slightly the cartridge to purposely misalign the cantilever zenith angle in the hopes of perfectly compensating for the manufacturer defect? Can it possibly matter when you and I both have gotten excellent results without considering any of this? Can we all get even lower distortion and better sonic performance by making this correction?

Going forward I'm going to inspect review samples, assuming my 200X microscope will magnify sufficiently. I think if you have spent more than $1000 on a cartridge you are entitled to one that has been properly manufactured in this regard and I'd return it unused rather than trying to compensate in the set-up for the problem. If you've spent many thousands of dollars and find this defect, I'd be pretty ticked off about it.

Your thoughts?