Michael: For years I've used the classic DB Systems protractor which appears to use the Lofgren A curve.

Looks to me as though trying Lofgren B would be a worthwhile effort. Any recommendations for a low cost Lofgren B based protractor?

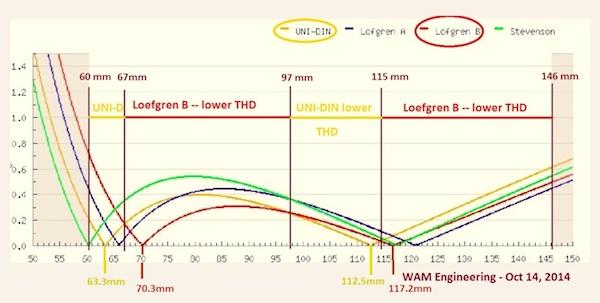

UNI-DIN Versus Löfgren B Just to Clarify

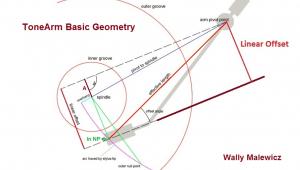

So to make sure you clearly understand what you are seeing: the lead in groove (represented by the shaded area) is to the right and the lead out groove (represented by the larger shaded area) is the left.

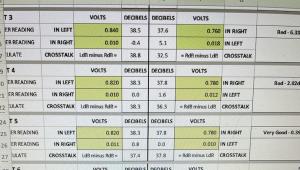

The "null" points are where the lines touch the graph's horizontal axis. So as you can see, the Löfgren "B" null points (where the stylus is tangential to the groove and therefore there is 0 LTE (lateral tracking error) are at 70.3mm and 117.2mm. The null points for Löfgren "A" (identical to Baerwald) are at 66.0mm and 120.9mm. The null points for UNI-DIN are at 63.3mm and 112.5mm. The Stevenson curve is shown in green

So what does this mean in practical terms? As you can see distortion is relatively high and the very beginning of the record for all curves, but plummets dramatically for all curves to the first null point. However Löfgren "B" distortion (and Stevenson) is lower than UNI-DIN for that portion of the groove surface and UNI-DIN's first null point is almost 5mm beyond Löfgren "B"'s first null. From 115mm to 97mm UNI-DIN's THD (total harmonic distortion) is lower than any of the other curves, but it is a relatively narrow area compared to the 97mm to 67mm segment where Löfgren "B" is considerably lower then UNI-DIN and Löfgren "A" (Baerwald) and especially Stevenson.

Beyond the second "null" points for all of these curves distortion dramatically rises but note that while Löfgren "B"'s second null point is a full 7mm before UNI-DIN's and therefore the distortion begins to rise well earlier than UNI-DIN's, UNI-DIN's distortion is way higher at that point and the two only meet (one rising, one falling) at the 67mm point. Still it is true that Löfgren's distortion toward the very end of a typical side is well higher than UNI-DIN's and as you can also see, Stevenson's distortion is plunging toward's the end of the side and only begins rising beyond the theoretical end of the side, which is why it is suggested (by some) for people who mostly play classical music.

However, given the far higher distortion over a larger swath of groove territory is that a worthwhile trade-off? I am not in the habit of asking questions and answering them for you so you tell me! My understanding is that the Rega paper overhang gauge is the Stevenson aligning or close to it. If you listen mostly to rock and pop music does the Stevenson curve make sense for you? Here I will answer the question because there's not doubt about the answer: NO!

Now as between UNI-DIN and Löfgren "B" please decide for yourself. My decision is to go with Löfgren "B" but I'm here to give you the facts, not here to tell you which alignment to choose. That is up to you. Keep in mind that compared to the distortions added by the rest of your system, my opinion is that all of these curves produce less.

- Log in or register to post comments

I've been using this template. My setup sounds great with 'A'. It does 'A', 'B', and some others.

http://www.vinylengine.com/turntable_forum/viewtopic.php?f=19&t=16849

...where does (the distortion from) lateral tracking error rate?

For example, in a certain price category, one could choose from pivoted tonearms from SME (cast magnesium) or VPI (3D printed composite) OR a tangential tracker from Clearaudio (aluminum and glass). Is tonearm material and bearing quality more important or are they trumped by the lower distortion from linear tracking?

This graph is of much help. It illustrates clearly the differences between curves that I have been reading about, but are hard to grasp when written. My protractor, a SMARTractor, has null points for Lofgren B DIN and IEC. What are the differences and which are we referring to in this post?

I meant Lofgren B DIN and Lofgren B IEC.

My protractor, a SMARTractor, which I think you have stated is what you use, has Löfgren A/B DIN and Löfgren A/D IEC. That was my question, which of the 2 curves is the "standard"?

I guess, the curves refer to a 9" arm length. Would be interesting to see also the curves for 12" for comparison how much lower realtive overall distortion is with 12".

Yet another fascinating post - thank you - I do however have some questions and I feel a template and survey coming on to measure the radius of the inside grooves of my records.

Questions that are making my brain hurt

1) I can't see a pattern in the graphs - see 2

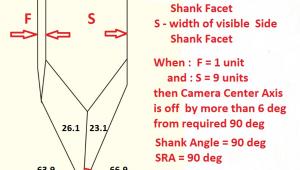

2) How can you the second null point be different if the first is the same unless you are comparing different arm lengths or different cartridge rotation angle from pivot point?

3) How does the SME arm with SME template compare? and are there any alternatives for SME set up?

Brilliant brain teaser on a groggy Sunday Morning

First Mikey, as I mentioned a few years back when I was able to purchase some seriously nice equipment, I tried to purchase Wally's tools. I emailed and telephoned his company several times with no response. So it is always frustrating to read that he has these cool tools and test results that you have access to, but not at least me. I don't know if anyone else has ever been able to purchase any of Wally's stuff.

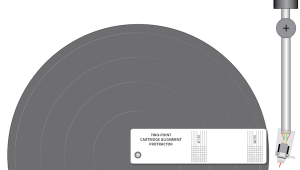

I forget who makes the etched glass protractor you use on your setup Dvd. I have the Fiekert, (about 4 years old, there is a newer version), one that comes with the Hi-Fi News test Lp, a MoFi geodisc, and the spindle adapter with cartridge alignment tool that comes with the Graham Phantom Supreme. I cannot state with authority which one is better.

I've had a same situation with the Wally Character. On the phone with him then he wanted me to call him back. It's a complete Joke. The guy is a crook And I know people that have paid for the shipment of protractor and gadgets and haven't been received anything. Also on the Vinyl forum several people have mention similar dealing with this Wally Character. Mikey why do you promote this guy when he is clearly ripping off people and asking people to send money to him and not shipping the product. You can be on the fence and prey on consumers. Mikey I find it hard to follow you DVD when you are using Wally's stuff. I wish you would start using tools that are available to the general public when you demonstrating setup. I have a VPI 3 and it doesn't come with a Wally skater or a mirror like protractor. It comes with a own protractor would it have been more productive to use the VPI protractor (I believe it's a

I've had a same situation with the Wally Character. On the phone with him then he wanted me to call him back. It's a complete Joke. The guy is a crook And I know people that have paid for the shipment of protractor and gadgets and haven't been received anything. Also on the Vinyl forum several people have mention similar dealing with this Wally Character. Mikey why do you promote this guy when he is clearly ripping off people and asking people to send money to him and not shipping the product. You can be on the fence and prey on consumers. Mikey I find it hard to follow you DVD when you are using Wally's stuff. I wish you would start using tools that are available to the general public when you demonstrating setup. I have a VPI 3 and it doesn't come with a Wally skater or a mirror like protractor. It comes with a own protractor would it have been more productive to use the VPI protractor (I believe it's a

So it looks like Lofgren B would be a strong winner on records with short sides like many of the 45 RPM reissues.

I have the Mint protractor from Yip in Hong Kong (Stevenson) as well as a Ken Willis protractor that has all the alignments; I've used it on a Rega p1, P3-24, Rp1, P5 and finally my new Rp8. I've tried out the Baerwald, Loefgren and stevenson alignments with multiple cartridges and have to say that I could never hear a difference between them in the end - My Ortofon 2m Blue had trouble in certain spots (the same ones) no matter which one I used and my Dynavector 20x2 tracks everything without issue with all the alignments. I like the Mint protractor because it seems most precise, so it's been Stevenson, which is closest I think to Rega's own geometry.

Thanks for the response. I made my WT 12" clone completely adjustable (even arm length to pivot), positionable and removable. When I position it for overhang there are audible effects - a skip per side and what sounds like record wear (my records sounded old and in need of replacement) - that appear totally gone to my ear when tracking using the underhang method. I'll be re-wiring it again shortly and installing my final headshell and I'll test it with overhang again.

Hi Michael, fully agree on Löfgren B as the best choice - even more so with 12 inch arms as long as everything is set up and measured correctly. I had the Smartractor but had a number of issues with it and sold it again (we talked about it briefly in Munich).

An easy to use and cheap protractor is Ken Willis' AccuTrak, www.accutrak.us, but it is custom made for specific arms hence not universal. I got three, one for each arm, still cheap. And finally, Wally is a great guy and he knows his stuff.

Is that a normal occurrence for the Ortofon? I was thinking of an Ortofon for a second cartridge and hadn't read that before.

On my arm and table it tracked well for the majority of albums - I could never completely get rid of IGD on some albums and there would be some distortion here and there other places once in a while. It's a good cartridge, but I went to a sae 1000lt and then the dyna 20x2 both of which which tracked a lot better for me.

I use Yip's best tractor from Honk Hong with my VPI Traveler and Ortofon 2M Black. It took me a long time (multiple hour-long sessions) to get it dialed right in, but now I hear zero distortion across the whole record. The music simply sounds like music.

i would like to get Yip's protractor. Can you post his contact info. Thanks.

i would like to get Yip's protractor. Can you post his contact info. Thanks.

Mr. Fremer,

It seems to me that linear tracking arms can be designed to meet the necessary requirements and provide the ideal solution. Mass (linear) or inertia (rotary) are factors when things need to accelerate. For movement in the plane parallel to the record, the grooves will create the acceleration which will vary depending on the radius from the center of the record (for the most part ignoring variable groove width). Anti-skate helps to balance this for rotary just as a bias spring or servo-controller does for linear. The amount of 'crabbing' from a linear is nil WRT to THD for a rotary (unless the bearing/controller design is crap). There's no particular reason that a linear arm can't be low mass. However getting a linear bearing to behave smoothly is usually the challenge which is why air bearings are used. I think if as much effort were put into linear trackers, the TT industry could create some very cost effective solutions that meet the resonance requirements (8-12hz) as well. Maybe we can resurrect the engineers from Nakamichi who developed the Dragon auto-azimuth controller and put them to task on this.

--Dale

Thank you Mr. Fremer for finally interpreting that tonearm geometry graph! Now that you explain it, I see it wasn't that difficult to read, but I'll be damned if I knew how to interpret them before.

Also...I have used the MintLP protractor and have had good results with it. It does take an inordinate amount of time to get it down though. However, for a few bucks more, the Dr. Feickhert updated protractor is so incredible easy to use, it's almost fun to try different tonearm setups. Just my opinion of course.

I spent some time years back downloading alignment protractors and testing them on my Project table I had at that time. Sorry but I don't recall the exact address where I found most of them. I see that Vinylengine has some of the most popular ones. But first off, if one wants to get by cheap, downloading a template is the way to go, but great care must be taken to get a decent one made. First off, I used thick presentation grade paper, and a quarter inch hole punch with a clear top, so you can see the center. And, if the print off does not have a reference ruler on it, then you just can't trust it. I had to play with the exact sizing of the printout to make that reference ruler come out exactly to scale. But, my findings back then were that the Lofgren B sounded best on my setup. So it's great to be vendiicated by your graph!

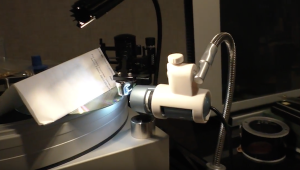

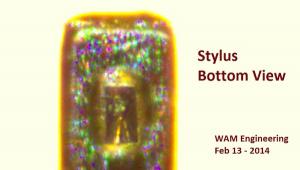

Since then I've moved up to a better 'table and also I used the VPI template that came with it. I'm not sure how their template compares to the Lofgren B? But I figured I wasn't going to second guess the maker of the arm/'table. But I have to agree with you that the distortion level differences shown in the graph are minimal. And getting your nul points set is a very good starting point, but once set, I found greater differences in sound by carefully adjusting the VTF and VTA to ear. Observing your styls with a magnifier and getting it close to manufacturer's recommended angles as best you can, and then making minor changes by ear, has brought my analog setup to the next level. So, setting your nul points and squaring up your cartridge is only the first step in getting the most from your cartridge. To me, anyway. Since you can't control where record makers put their lead in and lead out grooves, all we can do is try to keep distortion as low as we can between the nul's.

Please correct me if I'm confused. It has been known to happen.

And just to try and answer one commenter's question: How can a tonearm have two points of being square to the grooves? That is due to the way the headshell is skewed on the end of the tonearm. If the tonearm were straight, and the cartridge straight in line with it, then there would be only one nul point, or place where the needle was square to the grooves. But the way the headshell is offset, allows it to find two points where it will be square to the tangent of the circle, which is the record. Notice that they are not square in line, you must move the platter a short ways to find the second nul. Because the centerline of the cartridge is offset from the pivot point of the arm, it allows that centerline of the cartridge to find a tangent on two circles, one large and one small. I don't know if that clears anything up? Or only serves to confuse? But hey I tried. Anyone else care to take a stab at it? Most important thing to know is that it works, the designers of modern record players were some pretty smart cookies!

From my observation, although the Loefren B initially looks like it has the least amount of distortion across most of the record surface, it has the highest amount toward the end of the record. Seems to me the Uni-din has very little at the end of the record, and is fairly close to the Loefgren B across the whole record. So don't you think then that the Uni-din then has the least overall distortion ? Am I not looking at the graph correctly ?

Guess I will have to try both and buy a alignment protractor that does them both or all.

Have you played with the SMARTtractor ?

http://www.youtube.com/watch?v=oXQcdFF_Dro&feature=youtu.be

Looks very cool, very tempted to buy one just a bit pricy.

Measures spindle to pivot length accurately, sweet.

Kevin

Hi M.: You said: """ SMARTractor is a terrific tool """

I would like to know why or against what. The MINTLP protractor is unexpensive, accurate and with out caveats. With out knowing your arguments for me the MINTLP is a true " terrific tool ".

What do you think?

Greetings.

Thanks for the heads up on the review. Usually the better tonearms give you the spindle to pivot distance, although its not always easy to determine exactly like you said on some arms. I have an original well tempered labs classic, hoping to find a reference version with adjustable damping etc. Not real easy to determine its pivot point either. As for the unidin vs lofgren I wasn't sure how much of the last part of the record it starts to distort, good to know, thanks.

All records start at the edge, more or less...

Some records just don't have tracks all the way to the label. Makes sense then to optimize alignment for the first 90% of the side, the last 10% may not even be there...

Dear M./friends: """ So what does this mean in practical terms? """

IMHO and for every one first we have to understand the whole theory/subject in tonearm/cartridge alignment or kind of alignments:

- Baerwald, Stevenson, Bauer, Pisha and many more kind of alignments were based/foundation in the work made it in 1938 by LÖFGREN and his solutions through his calculations/equations where the object was and is to calculate the overhang and offset angle in any tonearm/cartridge combination. These are the main outputs in those equations that between other things gives both null points in any kind of alignment choosed and distortion levels.

The input variables need it to make the calculations are:

1- most outer groove record distance 2- most inner groove record distance and 3- tonearm effective length.

Does not exist null points for Löfgren B ( example. ) as a one and only solution: NO.

Null points depends directly not the kind of alignment but which outer/inner most groove distances we choosed as inputs in the equations/calculations. If we change these inputs null points will change it does not matters which kind of alignment we are using.

For years those two inputs were specified by the IEC and latter exist other standard DIN and exist JIS too ( any one of us can have our self standard too. ).

The IEC values are: 146.05/60.325 mm where the DIN: 146.3/57.5 mm

Through the calculations we achieve too the distortion levels that depends on where " are " the calculated null points. The calculations tell us the distortion levels in between the null points and outer both null points.

Overall the UNIDIN is higher in distortion level than Löfgren B in MF. example/picture.

Now, UNIDIN is it something special?: NO.

As I said everyone can have its " own solution " changing the inputs. If we use DIN against IEC standard the overall distortion level will be higher as is the uni-din.

So Löfgren or Baerwald has not an exclusive null points it only depends on the input choosed in the calculations ( there are several calculators over the net. ).

If we change the most inner groove distance input using IEC, this is that instead of 60.325 mm we take as input 54 mm then we have those null points in the picture as uni-din.

Normally when those two inputs are out of IEC standard overall distortion goes higher.

Can we heard at the inner grooves LPs a difference in better quality sound in uni-din than in Baerwald or Löfgren B?

If all those kind of alignments set ups were made accurately is almost imposible to hear. Why?, because the distortion level all over the recorded LP surface and at the inner grooves too is changing at each single groove with very low distortion values that can be really small as: 0.01% or maybe lower, IMHO no one can hear that distortion level changes even when that 0.01% goes to 0.2-0.3% we can't discern about.

Of course that if we use a poor cartridge tracker we can hear that in all kind of alignments.

I'm with the IEC standard ( I can change my mind in the future, who knows. ) and Baerwald or Löfgren B is ok if the alignment cartridge/tonearm is made it with absolute ACCURACY. This is the key word in " this alignment game ".

There is no perfect kind of alignment, in all exist trade-offs. Changing null points only define where we will have the diferent distortion levels through the recorded LP surface.

Why do you think the MINTLP protractor was and is so succesful? not only for its very low price but mainly for its accuracy do that the protractor is dedicated in specific not only to your tonearm but your TT too. Accurate.

So, any one of us can " invent " a new " black thread " for tonearm/cartridge alignment just changing one or those two inputs.

In the other side i would like to say that: LÖFGREN made maybe the greatness historycal audio contribution for you, me and everyone can for many years and many years to come follow enjoying our tonearm/cartridge combination listening in the right way the MUSIC we love.

My humble " hat off " for him.

Have fun!

That's exactly what Stevenson did it manipulating/changing the input to make that coincide one of the null point as the most inner groove distance and that's why overall Stevenson alignment has so higher distortion levels.

I can't understand why any one today can follow using Stevenson alignment when he can choose for better one as Baerwald or Löfgren B in favor of listening MUSIC.

Greetings.

Dear M./friends: I forgot, we can change too the effective length distance input to the calculations ( with/in the same tonearm we own. ).

If instead say 250 mm , that is the manufacturer spec ( example. ), we choose 253 mm the calculations will gives us a different offset angle, different overhang figure and diferent pivot to spindle distance.

Obviously that for we can change the EL input value we need that our tonearm headshell has slots with enough length to set up the cartridge to that new overhang and offset angle.

Normally if we go with a higher effective length distortions goes a little ( tiny ) lower and sometimes we could hear something diferent or maybe can't hear any change in the quality sound perfromance.

We can make anyb changes we want it. I prefer to follow Löfgren contribution and tonearm manufacturer effective length spec. Btw, if we know the tonearm effective length we don't need to know the pivot to spindle tonearm mounting distance because this comes after calculations for difference with the overhang calculated.

Regards.

Seems like you're comparing apples and oranges here. UNI-DIN is specified for DIN groove radii. The null points for Stevenson and the Lofgrens you were using are calculated for IEC specs. You'd have to use DIN specs for a fair comparison.