Tri-Planar Tonearm Owner Alert!

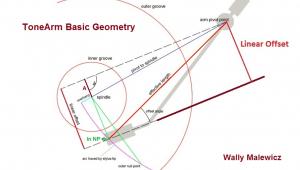

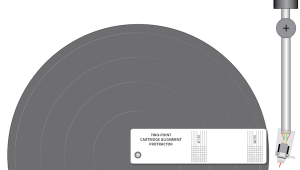

Before a packed house I explained that if you buy a 'table with a non-factory drilled arm board and even if it has been drilled by the turntable manufacturer, it is a good idea to measure the pivot-to-spindle distance because if it is incorrect, it will produce incorrect overhang results.

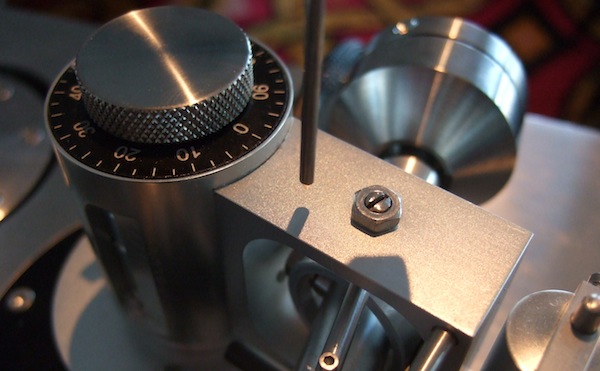

"In this case," I joked, as I placed over the spindle the Dr. Feickert protractor, "the arm board was drilled by the tonearm's German distributor so I have every reason to believe it has been done to perfection."

However, when I measured the pivot to spindle distance, which Tri-Planar specifies as 233.5MM, I found it to be considerably out of spec and closer to 238, which is way off. I told the crowd that it would probably be difficult to set up the arm with the proper overhang and that proved to be the case.

When I got back downstairs after the seminar I related to the German distributor what had just happened. He was flabbergasted and flustered. "That is impossible!" he insisted but he then backed down saying "Wait! I did not have the actual factory jig yesterday because it was in transit from the manufacturer. Instead, I used a 'jig' that was a piece of paper he'd emailed me and perhaps the print-out was not to scale. But tomorrow I will have the actual jig and I will re-cut the armboard and it will be perfect!"

The jig arrived the next morning, he re-cut the arm board and later that day I did another seminar, beginning by relating what had happened the previous day. This time the importer stood watching just off to the side, hands folded.

I again explained the importance of checking the pivot-to-spindle distance, finishing with "but this time I'm sure it will be perfect."

Guess what?

it was off by the same amount!

"Impossible!" he exclaimed, but the Feickert tool did not lie and he was left scratching his head while I went through the set up as best as I could, though the stylus could never reach the proper location per the spec'd 233.5 pivot-to-spindle distance. Yes, with a gauge like the Feickert, if you adjust the gauge to the actual pivot-to-spindle distance you can get an approximately correct overhang setting but it is simply not to spec. And ironically if you use the one supplied by Tri-Planar, you will absolutely get the wrong result because it is not referenced to the actual number, but rather to the spec'd number.

After the seminar we went downstairs to check the work and as expected, the German importer had cut the hole in the board precisely where the jig had instructed! So as it turned out the jig supplied by Tri-Planar was wrong!

Upon my return to America I called up Tri Mai, who had purchased the company some years earlier from the original designer the late Herb Papier. His response upon being told the news was odd and not what I was expecting (which was some kind of initial shock followed by skepticism followed by delayed gratitude). He then told me that if you twist the jig in a particular way it will give you the correct result. "But there's nothing in the jig instructions about doing any of that, so I suggest you either correct the jig's manufacture or you clarify that in the instructions!"

And that's where I left it. At some point I would like to revisit the arm or perhaps review the 12" version.

Cut to last week. On Sunday morning after the Capital AudioFest, I drove down to VA to visit a friend I'd made through this website and to install a replacement Dynavector Karat 17D for the one he'd bought just a few months before and accidentally destroyed.

He'd bought a nice, new package consisting of a Tri-Planar arm, VPI turntable and Karat 17D cartridge sold to him by a a gentleman whose name I will not divulge other than to say he sells pricey but very good and carefully picked used records and that he has written putrid things about me that can still be found on his website.

So what was the first thing I did? Right! And? The pivot-to-spindle distance was off in excess of 4MM, producing a pivot-to-spindle distance of around 238MM.

Exacerbating the error was the fact that the 17D has a short cantilever. I had brought along the Wally gauge, that like the one Tri-Planar supplies assumes a correct pivot-to-spindle distance. Even with the cartridge pushed all the way forward in the headshell, I could not get it far enough forward to correctly set the overhang. It was close, but in my world, close is not close enough! It shouldn't be in your world either.

So what happened? I'm not sure whether the installer used an old, pre-2009 jig or even if Tri-Planar has produced a new jig or revised instructions. All I know is that the armboard for this brand new Tri-Planar had been incorrectly drilled.

My feeling is that even if you are drilling an arm board using a factory-supplied jig, you are obligated to double check the pivot-to-hole-you-are-about-to-drill-in-the-customer's-arm -board distance, especially if the hole being drilled is into a virgin plinth and not into a replaceable plinth! In this case, fortunately, the board can easily be replaced.

So, if you own a Tri-Planar arm, the armboard of which was drilled by a dealer, or even by you using the supplied jig, do yourself a favor and measure the pivot-to-spindle distance. It should be 233.5. You can easily make an accurate measuring device by drilling a 7.2MM hole that bisects the 0mm line on a plastic ruler, then placing it over the spindle making sure to keep it parallel to the platter surface as you swing it into place.