Something tells me Tom Port is going to blame that incorrectly drilled Scout on something else...

Tri-Planar Tonearm Owner Alert!

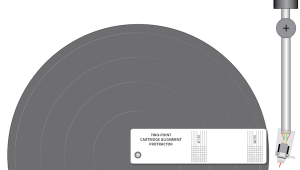

Before a packed house I explained that if you buy a 'table with a non-factory drilled arm board and even if it has been drilled by the turntable manufacturer, it is a good idea to measure the pivot-to-spindle distance because if it is incorrect, it will produce incorrect overhang results.

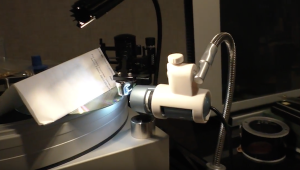

"In this case," I joked, as I placed over the spindle the Dr. Feickert protractor, "the arm board was drilled by the tonearm's German distributor so I have every reason to believe it has been done to perfection."

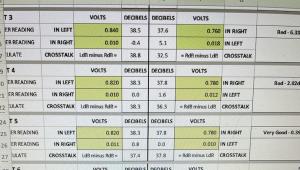

However, when I measured the pivot to spindle distance, which Tri-Planar specifies as 233.5MM, I found it to be considerably out of spec and closer to 238, which is way off. I told the crowd that it would probably be difficult to set up the arm with the proper overhang and that proved to be the case.

When I got back downstairs after the seminar I related to the German distributor what had just happened. He was flabbergasted and flustered. "That is impossible!" he insisted but he then backed down saying "Wait! I did not have the actual factory jig yesterday because it was in transit from the manufacturer. Instead, I used a 'jig' that was a piece of paper he'd emailed me and perhaps the print-out was not to scale. But tomorrow I will have the actual jig and I will re-cut the armboard and it will be perfect!"

The jig arrived the next morning, he re-cut the arm board and later that day I did another seminar, beginning by relating what had happened the previous day. This time the importer stood watching just off to the side, hands folded.

I again explained the importance of checking the pivot-to-spindle distance, finishing with "but this time I'm sure it will be perfect."

Guess what?

it was off by the same amount!

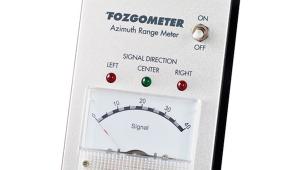

"Impossible!" he exclaimed, but the Feickert tool did not lie and he was left scratching his head while I went through the set up as best as I could, though the stylus could never reach the proper location per the spec'd 233.5 pivot-to-spindle distance. Yes, with a gauge like the Feickert, if you adjust the gauge to the actual pivot-to-spindle distance you can get an approximately correct overhang setting but it is simply not to spec. And ironically if you use the one supplied by Tri-Planar, you will absolutely get the wrong result because it is not referenced to the actual number, but rather to the spec'd number.

After the seminar we went downstairs to check the work and as expected, the German importer had cut the hole in the board precisely where the jig had instructed! So as it turned out the jig supplied by Tri-Planar was wrong!

Upon my return to America I called up Tri Mai, who had purchased the company some years earlier from the original designer the late Herb Papier. His response upon being told the news was odd and not what I was expecting (which was some kind of initial shock followed by skepticism followed by delayed gratitude). He then told me that if you twist the jig in a particular way it will give you the correct result. "But there's nothing in the jig instructions about doing any of that, so I suggest you either correct the jig's manufacture or you clarify that in the instructions!"

And that's where I left it. At some point I would like to revisit the arm or perhaps review the 12" version.

Cut to last week. On Sunday morning after the Capital AudioFest, I drove down to VA to visit a friend I'd made through this website and to install a replacement Dynavector Karat 17D for the one he'd bought just a few months before and accidentally destroyed.

He'd bought a nice, new package consisting of a Tri-Planar arm, VPI turntable and Karat 17D cartridge sold to him by a a gentleman whose name I will not divulge other than to say he sells pricey but very good and carefully picked used records and that he has written putrid things about me that can still be found on his website.

So what was the first thing I did? Right! And? The pivot-to-spindle distance was off in excess of 4MM, producing a pivot-to-spindle distance of around 238MM.

Exacerbating the error was the fact that the 17D has a short cantilever. I had brought along the Wally gauge, that like the one Tri-Planar supplies assumes a correct pivot-to-spindle distance. Even with the cartridge pushed all the way forward in the headshell, I could not get it far enough forward to correctly set the overhang. It was close, but in my world, close is not close enough! It shouldn't be in your world either.

So what happened? I'm not sure whether the installer used an old, pre-2009 jig or even if Tri-Planar has produced a new jig or revised instructions. All I know is that the armboard for this brand new Tri-Planar had been incorrectly drilled.

My feeling is that even if you are drilling an arm board using a factory-supplied jig, you are obligated to double check the pivot-to-hole-you-are-about-to-drill-in-the-customer's-arm -board distance, especially if the hole being drilled is into a virgin plinth and not into a replaceable plinth! In this case, fortunately, the board can easily be replaced.

So, if you own a Tri-Planar arm, the armboard of which was drilled by a dealer, or even by you using the supplied jig, do yourself a favor and measure the pivot-to-spindle distance. It should be 233.5. You can easily make an accurate measuring device by drilling a 7.2MM hole that bisects the 0mm line on a plastic ruler, then placing it over the spindle making sure to keep it parallel to the platter surface as you swing it into place.

- Log in or register to post comments

I am surprised that more manufacturers don't supply a plastic jig that would fit over the spindle with a hole at the other end to mark the pilot position for the arm mount. For the price of some tables today that would seem like a great way for their customer to get max enjoyment from their purchase.

I loved the old Shure Type V cart body cradle that made mounting and set up of the Type V almost fool proof. It would seem like something that Ortofon could do for their new Red to Black range of carts. I'm sure sales are brisk for them. If it didn't fit in the cradle surely the tonearm mount is incorrect.

surely incorrectly setup equipment would tarnish one's findings when using said equipment in a professional capacity ?

and this is one professional who in the past has admonished others for using poorly setup equipment.

oh the irony !

hahahaha

"I drove down to VA to visit a friend I'd made through this website"

Heads up, Fremer fans ;)

With all this fuss about overhang and spindle distance, I can't help but wonder, Michael, what your take is regarding Well Tempered's use of a fixed cartridge mounting position on their current tone arms.

This subject thread should surely increase your popularity with the Triplanar folks.

I was toying with the idea of putting one of their arms on a refurbed Garrard 401.

Not so much now until or if the Triplanar folks reply/explain.

The devil is indeed in the details.

Kind of makes you wonder what the Triplanar owner's listening experience is like.

Assume nothing!

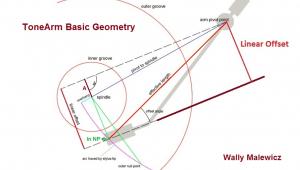

Bear in mind that if the arm is positioned incorrectly on the armboard, it may still be correctly aligned with a triangulation type alignmnet protractor, such as the Feickert that Michael mentioned earlier. If the deviation of the actual spindle to pivot distance from the specified spindle to pivot is not so great that the arm length and slots in the headshell still allow for the cartridge to align to the grid of the protractor, you are good to go. A non-triangulation alignment system is predicated on fixed points (spindle to pivot distance) that need to be exact for the device to provide accurate results. As Michael mentioed, there is usually a spindle to pivot "margin of error" that is allowed for in these devices, which is typically 0.5mm, which is quite a ways from the 4mm Michael encountered.

I've got a used Tri Planar MK lV I'm waiting to install on an arm pod I'm having made. I've got the jig which I purchased from Tri 2 months ago.

Should I be able to re drill the spindle hole in my jig 4.5 mm closer to the mounting holes to achieve the proper placement? If it's mounting incorrectly at 238 mm and 233.5 is the correct placement: 238 - 233.5 = 4.5 mm difference. Yes?

Thank for pointing this out in a post before I made my drilling error-

I've got an old version of this arm (maybe 12-15 years old?) and used the supplied plexi jig when drilling my plinth years ago. This article made me a bit nervous so I just checked my distance and it measured in at approx 233mm. Whew! Used a Wallytractor when aligning, and all seemed well then. Relieved my jig isn't off...

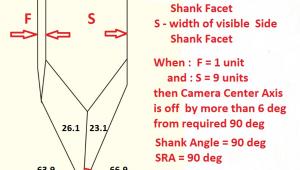

I have the latest Tri-Planar arm mounted on a Micro Seiki RX-5000. The larger Micros employ metal arm "boards" that can swivel on a round post when their clamps are loosened. You mark the drilling locations on the arm mounting board with the board and arm positioned approximately where they will have to be for correct pivot-to-spindle distance, esthetics, clearances, etc. Once the arm is secured onto the board, you swivel the arm board and its now captive arm until you've got the exact pivot-to-spindle distance you desire. Then you tighten a beefy hex-head machine screw in the clamping portion of the arm board to apply an Asian death-grip onto the base post, and nothing will move, even in a tsunami. Oh yeah, check the distance again after tightening to appease your OCDness. Want to hear how 233.75 or 232.9mm distances might affect Norah’s throat sounds? Knock yourself out; it’s that easy. I modified the fairly useless Tri-Planar-supplied jig to make a trammel with two adjustable spikes spaced at precisely 233.5 mm. Norah sounds OK there, but I’m lazy. Spikes are from the base of a Quad-ESL-63 in case that matters. By adjusting the spike lengths appropriately, the trammel is set exactly parallel to the platter, when one spike goes into the convenient little hole in the center of the spindle, while the other spike goes into the center of the screw slot for the arm’s pivot bearing. I wear magnifying glasses so that I can count molecules on either side of the spike to make sure it’s dead center. By the way, the gunmetal bronze arm board itself weighs more than an LP-12 platter and the whole table weighs more than a pallet of LP-12s, but I digress...

@BB,

You wrote, "one spike goes into the convenient little hole in the center of the spindle, while the other spike goes into the center of the screw slot for the arm’s pivot bearing."

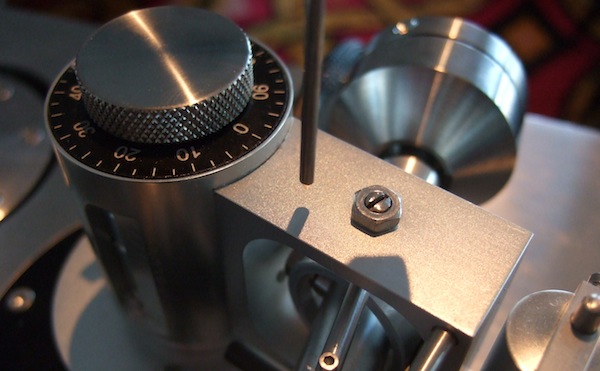

The photograph Michael posted at the beginning of the thread shows the measurement at the spindle screw.

I have a MK VII and I don't see a spindle-centered convenient hole. Perhaps this was present on earlier models?

In my case, the sliding tonearm mount of the Luxman allowed for it to be position using the provided guide. After a few adjustments, the locations of the holes were identified and drilled. If the plate was left in the same location, the pivot-to-spindle distance would be off, but using the Feickert later, the correct distance was found.

I was not so fortunate with the mounting of this tonearm on my previous turntable's arm board. I was not able to rotate the tonearm base far enough to get the desired distance.

I was referring to the "convenient little hole in the center of the spindle" of the PLATTER of my Micro Seiki RX-5000. Sorry for the confusion. Some tables have a little hole in center of the platter spindle; others do not. I Googled images of your Luxman PD-444, and it appears that you do not have that convenient little hole, but more of a dome there. Even with the dome, with care you should be able to hold a trammel centered over it. If not, you'd have to concoct a slip-on post that does have a hole in the top. But it sounds as though you got it working anyway.

I think the main problem is that the way the bolts that mark the hole positions fit through the plastic bar, leaves a lot of slop in where they land on the board. The one time I mounted a Tri-Planar from scratch I also used the Feickert tool.

I use the Feickert protractor. I was setting up a cartridge for a friend on a Kenwood "granite" table with the OEM tonearm. Same problem: spindle to pivot was 206mm instead of 215mm (and this straight from Kenwood's factory) as in the arm's secifications. It was about 7-8mm short on overhang with the cartridge all the way forward in the headshell. I then tried an Ortofon two-point protractor. Null points were different (wider) than Baerwald and settled on that.

Longfern is different as is Stevenson. Well Temepered's original tonearm comes with yet a different protractor that is neither of the above. Garrott Brothers, Oracle, all different. It seems that every tonearm and cartridge manufacturer makes up their own rules. And the latest Well Tempered tonearm on the Amadeus table has no provision for alignment whatsoever. I read in an interview the designer (W. Firebaugh?) doesn't think it is important and all you will get is a bit of extra second harmonic distortion.

What is going on here? Can't they be bothered to work out the mathematics on the subject? How many "correct" alignments are there? Arrrgh!!

The Jig is up.

Thank you, Michael, for informing the public and I about your difficulties with the Tri-Planar pivot-to-turntable spindle measurement.

I extend my apologies to any Tri-Planar customers who may have encountered similar set-up issues. If your turntable spindle-to-tonearm pivot is more than 233.5 mm then loosen - but do not remove - the three mounting screws at the base of the tonearm and move the tonearm slightly toward the turntable spindle or rotate the Tri-Planar tonearm clockwise to achieve 233.5mm. If the turntable spindle-to-tonearm pivot is less than 233.5 mm, move the tonearm away from the turntable spindle.

When setting up the cartridge, the arm may need to be moved slightly. This is why #10-24 screws are recommended for the 0.250” mounting holes on the tonearm base, allowing for 0.065” of free space to move in all directions.

Based on your feedback, I will develop additional tools along with the drilling template to assist with achieving the exact 233.5mm dimension. In addition, I will update the instruction manual with pictures so setting up the turntable, tonearm and cartridge will be correct and consistent.

If you have any difficulty, please give me a call at 612-623-0922 or Email: tri@triplanar.com. I am available 9:00 AM to 6:00 PM, Monday to Friday and most weekends too. We are here to serve you!

Thank you for supporting Tri-Planar. Wishing you well and enjoying music.

Tri Mai

Tri (a very appropriate name!): Thanks for chiming in. May I suggest you consider including an adjustable trammel as I described above? A span of plastic similar to your drilling jig (or repurpose that same included piece of plastic) or of metal, with two height-adjustable spikes that are held rock-solidly at the 233.5 mm spacing with nuts (and no slop). Glue a bubble level on top of the span to make sure the relative heights of the two spikes have been set correctly at level. I don't think you'd need or want to have a spindle hole on one side - just a spike on both ends. One spike rests into your upper pivot locking screw slot. The other should be centered on the spindle. You hold it in both your hands the whole time and then set it aside. It doesn't need to rest anywhere on the 'table. I think anyone can "eye ball" the spike on the spindle center to better than 0.5mm. The trammel is just used to check the distance and then it's set aside with each tweak of the distance. If you wanted, you could include a slip-on cap for one spike that does slide over the spindle to secure one end.

Hey, this is not bad publicity - let's take this opportunity to salute one of the greatest tonearms ever made! Almost no other arm does space and time like the Tri-Planar.

I own and WORSHIP a Triplanar arm, MK VII, version 2. Last arm I'll ever need. Like others, I found the jig not the most useful, made my own with stiff coats hanger wire and two small nails as markers. Anyways, I used a friend's Feikert to set it up, worked well, but later bought a Mint protractor. What an improvement! The lines of the Mint are thinner than the Feickert, which lends to greater accuracy (and more cursing, ha ha! The thinner lines, while more accurate, make set up more intense, but the results are worth it). We all know inner tracks don't sound as good as outer, but with the Mint, I was able to fine tune the cart more to get a very notable improvement in tracking/audio quality for final cuts on LPs (NOT subtle!) The only drawback (besides the extra care/time needed in set up with the thin line) is that the protractor is cut for the exact length of your arm, it's not universal. I'm still convinced it's possibly the most accurate alignment tool you can get (esp. since Wallytractor is gone).

I have to agree with Mark. I also bought a Mint protractor for my Tri-Planar. it works very well. I feel like I've really got my alignment spot-on with the Mint's very precise markings.

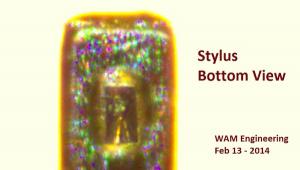

Since the optimum alignment is based on a combination of 3 parameters: spindle to pivot, pivot to stylus, and offset angle. Since 2 are fixed, even though one is not per spec, you may be able to vary the pivot to stylus in this case to get optimum Baerwald alignment.

Regarding protractors. I bought the Feickert jig and found, when verifying its' accuracy with metric scales, that it was off by 1mm. While the beam markings were fine, I suspect the pillar screw holes were incorrectly drilled. Interestingly, I used 3 different metric scales and found 1 of them was inconsistent with the other 2.